Measured Elongations vs. Calculated Values in Post-Tensioning: Why the Difference Matters

By MONBALLIU ConsultingIntroduction: A Key Quality Check in Post-Tensioned Structures

In both internal and external post-tensioning systems, comparing measured elongations with calculated theoretical values is crucial. Discrepancies can indicate issues like misalignment, excessive friction, or blocked ducts.- How elongations are calculated

- Measurement techniques for internal and external PT

- Causes of discrepancies

- Acceptable deviation thresholds

- Diagnostic steps

How Calculated Elongation is Derived

Based on:- Prestressing force (P)

- Tendon length (L)

- Cross-sectional area (A)

- Modulus of elasticity (E)

- Friction and wobble coefficients (μ and k)

- Tendon profile curvature

- Anchor set allowance (Δa)

On-Site Measurement Techniques

Internal Tendons

- Measured via jack piston stroke

- Anchor set correction applied

- Often stressed from one or both ends

External Tendons

- Measured using displacement sensors or jack gauges

- Complemented by load cell data

- Influenced by deviation saddles

Common Causes of Discrepancies

| Cause | Internal PT | External PT |

|---|---|---|

| Friction losses | Variable from duct deformation | Influenced by saddle design |

| Misalignment | Can block ducts | Adds friction/curvature |

| Duct damage during concreting | Common issue | Less relevant |

| Anchor set variability | Significant | Less so |

| Wedge slip | Often underestimated | More controlled |

| Jack calibration | Affects both | Affects both |

What’s an Acceptable Deviation?

General guideline: ±7% to ±10%Internal PT is more prone to variation. External PT systems, though less sensitive, can still be affected by small geometric changes.Diagnostic Process When Values Don’t Match

- Check jack calibration

- Compare measured force with elongation

- Inspect tendon profile for alignment or blockage

- Verify anchor set assumptions

- Review site-specific friction coefficients

Practical Recommendations

- Record both elongation and force

- Use mock-up trials for complex tendons

- Double-end stress long internal tendons

- Instrument test tendons for external PT

- Review as-built tendon profiles

Conclusion

Measured elongation is essential for verifying tendon performance—particularly when direct inspection isn’t possible. Acceptable deviations should be understood, and outliers investigated with care.

Visual Aids

1. Friction Loss Graph

2. Idealized Tendon Profiles

Source: https://www.researchgate.net/figure/Example-2-Idealised-Tendon-Profiles_fig1_292548415

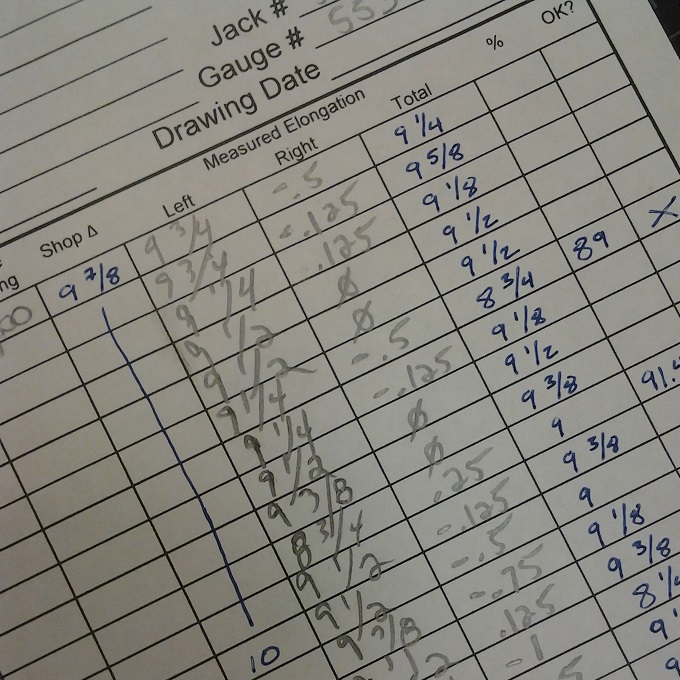

3. Elongation Measurement Example

Source: https://evstudio.com/reviewing-elongation-reports/

💬 Let’s Talk

Need support with tendon inspection, troubleshooting, or repair strategy?

📧 Contact michel(@)monballiu.net today !